Middle School Students Tour GSM’s Tomah Facility

See what a group of middle schoolers learned during a visit to our facility in Wisconsin.

Home / Capabilities / Machining

OEM programs need accuracy and repeatability. General Stamping & Metalworks delivers industrial metal machining built for production: CNC milling and turning, tight tolerances, and efficient changeovers from prototypes to volume. We optimize toolpaths and coordinate machining with laser cutting, bending, welding, and assembly, so there’s one plan and fewer handoffs.

Our extensive metal manufacturing capabilities eliminate the need for multiple manufacturers, giving OEMs one timeline and a smooth output from concept to delivery.

As the metal machining company of choice, we align forecasts, stage material and tooling, and manage WIP so your schedule holds, even as suppliers or demand shift.

OEMs get the advantage of the breadth and depth of our expertise, improving manufacturability and reducing costs.

GSM runs industrial metal machining on a production floor built for accuracy and pace. Parts flow from CNC milling and turning straight into our other capabilities with no hiccups. As a leading metal machining company, we offer comprehensive supply chain management and:

Industrial metal machining removes material from bar, plate, castings, or weldments to create precise features. CNC controls read your CAD, generate toolpaths, and drive cutters along various axes while managing feed, speed, and coolant. The result: accurate faces, slots, pockets, bores, threads, and profiles that meet the print. GSM features:

Our core operations include milling for flatness and contours, turning for OD/ID features, and drilling, tapping, boring, and reaming for tight, repeatable holes. Smart fixturing keeps parts stable, and finishing passes refine edges and surface quality. We use machining for prismatic parts, threaded features, sealed surfaces, and tight true-position on prototypes and production runs alike. Our metal machining services complement our forming and cutting by adding critical details in combination with laser cutting, stamping, or bending.

CNC starts with your model and a machining plan. Our programmers select tools, design fixtures, and create toolpaths in CAM, then input specialized coding with setup sheets that spell out everything the cell needs to run the part.

On the floor, we load stock, clamp it in a rigid fixture or vise, and set zeros with probing. We verify tool lengths and diameters, run a dry check, and cut. Adaptive roughing clears material fast; high-speed strategies manage heat and chip load; finishing passes lock in surface quality. Live-tool lathes add milled features in a turning cycle, and 4-axis indexing reaches tough faces in a single setup: true CNC metal machining built for throughput.

We keep accuracy tight during the run. In-process probes check bores and faces, tool wear offsets update automatically, and SPC catches drift before it becomes scrap.

Coolant delivery and chip evacuation protect edges and extend tool life.

Throughput matters, so we stage tools, use quick-change fixturing, run pallet systems and bar feeders where they make sense, and schedule cells to match your forecast. Parts leave machining ready for further services on the same production plan, keeping your program moving.

GSM machines carbon and high-strength steels and stainless (300/400 series), among other materials. We cut plate, bar, castings, and welded fabrications, then carefully fixture to control deflection on thin walls and long parts. If your print calls for secondary ops or assembly, we keep the same routing on our floor to hold alignment through the build.

We practice precision metal machining by quoting to your drawing and engineering the process to hit the callouts: true position, flatness, perpendicularity, and surface finish. Expect accurate holes and consistent geometry that move directly to forming, welding, or assembly without rework.

Our CNC cells sit next to laser cutting, stamping, bending, welding, tube work, and assembly areas, so parts move through a shared routing without detours. Our engineers line up details across processes, plan bend and weld allowances, and lock in targets before the first chip falls. In-process checks at machining feed downstream fit-ups, so holes land where they should and surfaces mate cleanly in final assembly.

With this set-up, our metal machining services deliver quick iterations and steady volume. Palletized workholding, staged tooling, and coordinated changeovers keep queues short while kitting and sub-assemblies leave the floor production-ready.

If you want a partner that ties industrial metal machining into a complete build, GSM makes it happen with tight tolerances, predictable lead times, and large-format components handled on one integrated production track.

Spend a few minutes on the floor with GSM’s production team. This video shows how we keep schedules tight and why OEMs rely on our metal machining at scale.

Send your print, material, and quantities, and our team will price the job and set a clear lead time. As a trusted resource in the $402.6 billion global machining market, we run industrial metal machining on the same floor as all our processes, so one request covers the whole build. Want to fine-tune tolerances or finishes? Talk directly with an engineer and lock the plan before the first chip falls. Contact GSM or request a quote today to keep your schedule on track.

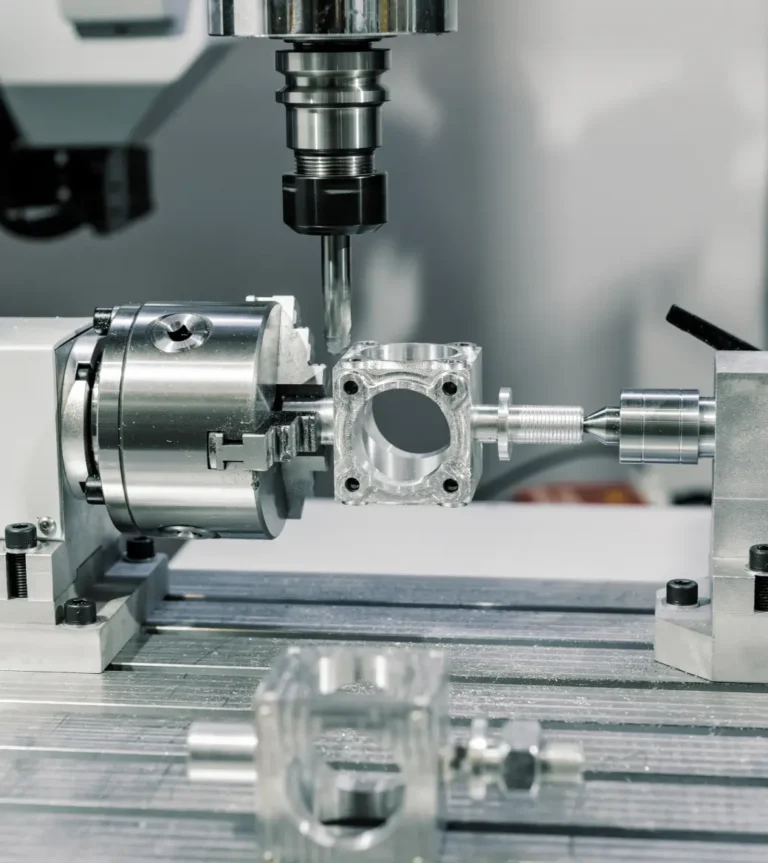

See machined parts straight from our floor, featuring tight bores, clean pockets, crisp threads, and flat mating faces. Every image reflects the precision and repeatability GSM delivers on OEM programs.

Yes. We accept common CAD and drawing formats and provide feedback before we begin.

We offer CNC milling and turning, along with drilling, tapping, boring, reaming, and threading. We also handle sawing, surfacing, and light deburring so parts move cleanly into downstream operations.

Yes. We launch prototypes, prove the process, and scale to production on the same cells and team, delivering fast changeovers and repeatable results.

See what a group of middle schoolers learned during a visit to our facility in Wisconsin.

Discover why Toyota Material Handling named GSM one of its Premier Suppliers.

Learn all about Kellen Zollinger, our chief financial officer.