Home / Capabilities

Our comprehensive in-house capabilities allow us to deliver high-quality, cost-effective solutions at every stage of the manufacturing process. By combining advanced technology with skilled expertise, we help our customers bring products to market faster and more efficiently.

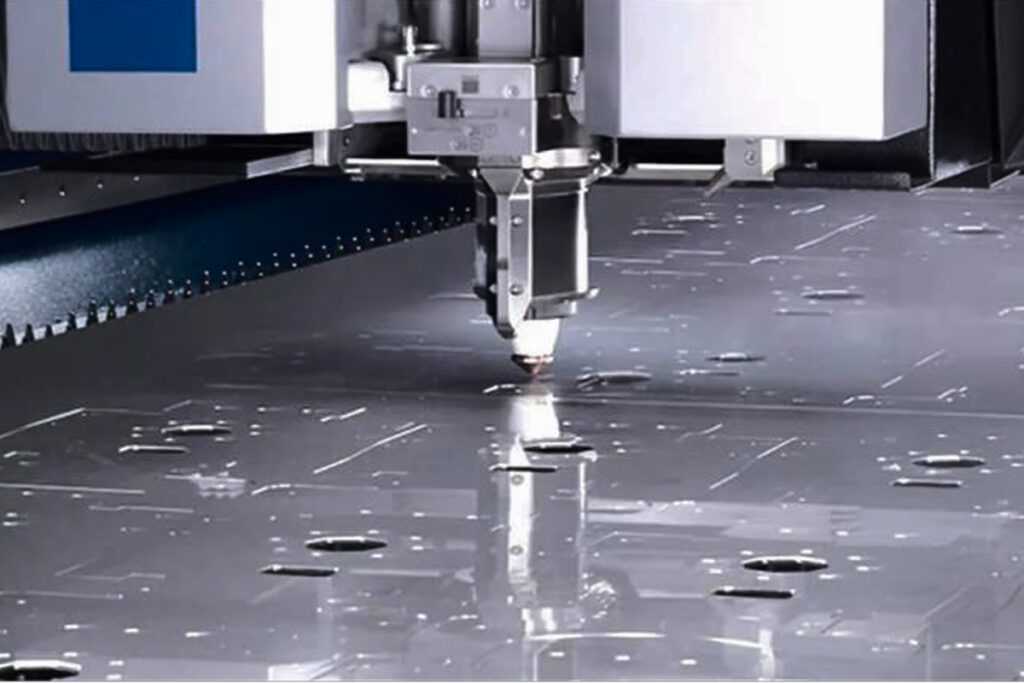

Laser cutting is a method to create precise and intricate shapes from various metals.

By using this high-powered laser beam, this process ensures clean cuts with minimal waste.

This process requires very little setup cost and no tooling, making it an efficient and cost-effective solution for production.

Tube Fabrication is a precise and versatile process used to cut, bend, and shape metal tubing.

This process allows for the creation of custom tubular components with tight tolerances, smooth finishes, and minimal material waste.

Warehousing provides secure storage and efficient management of raw materials, components, and finished products

With organized inventory systems and strategic logistics, warehousing ensures timely access to materials and reduces lead time

Eco-friendly logistics such as returnable containers, means fewer disposable materials, better protection for parts, and a streamlined process that benefits the environment and our customers

Tool and Die manufacturing is an engineering process used to design and produce custom tools, dies, and molds for metal stamping, forming, and cutting applications.

Properly designed and maintained tooling can extend production life and reduce downtime, leading to high efficiency and cost savings in metal fabrication.

Roll forming is a continuous metal forming process that shapes metal strips by passing them through a series of rollers, forming the desired shape.

This process significantly lowers production costs and reduces material waste.

Let our expertise work for you. Contact us today to discuss your metal fabrication needs and receive a competitive quote.