Middle School Students Tour GSM’s Tomah Facility

See what a group of middle schoolers learned during a visit to our facility in Wisconsin.

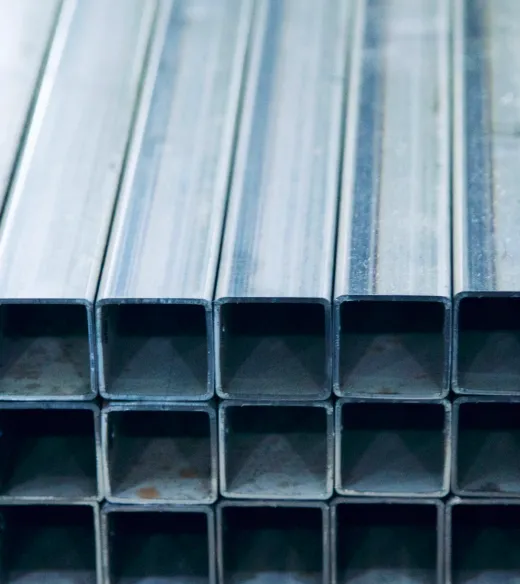

Home / Capabilities / Metal Tube Fabrication

General Stamping & Metalworks (GSM) provides metal tube fabrication as a core capability, transforming raw tubing into precision components ready for demanding OEM applications. Using advanced bending, cutting, forming, and finishing technologies, we deliver parts that combine accuracy, strength, and clean aesthetics—whether it’s a single prototype or a high-volume run. General Stamping & Metalworks (GSM) provides metal tube fabrication as a core capability, transforming raw tubing into precision components ready for demanding OEM applications. Using advanced bending, cutting, forming, and finishing technologies, we deliver parts that combine accuracy, strength, and clean aesthetics—whether it’s a single prototype or a high-volume run.

We offer an extensive range of metal manufacturing capabilities, eliminating the need for multiple manufacturers.

We excel in providing enhanced supply chain stability and dedicated support for minimal disruptions.

We offer a state-of-the-art facility equipped to tackle projects requiring large metal components.

Our expertise helps improve manufacturability and reduce costs.

Quality, speed, and reliability are not add-ons—they’re built into every GSM program. Our engineers, operators, and quality team work together to ensure every metal tube fabrication project meets your specifications, your timeline, and your cost targets without surprises.

At its simplest, metal tube fabrication is turning straight lengths of tubing into functional parts through bending, cutting, forming, and finishing. At GSM, we apply this craft to everything from compact brackets and handrails to long structural frames and chassis components.

Our CNC-controlled systems create smooth, repeatable bends with tight radii and multi-angle geometries in steel, stainless, and specialty alloys. Complex patterns are handled with the same precision as simple sweeps.

Automated saws, lasers, and end-forming tools deliver clean cuts, accurate lengths, and tailored end profiles, so your components fit perfectly into downstream assemblies.

While many shops stick to light-duty work or a single fabrication process, GSM combines the flexibility of a prototype shop with the muscle of a large-scale manufacturer. Our tube fabrication areas handle everything from delicate, tight-tolerance components to oversized tubular sections stretching over 15 feet.

Inside our facilities, you’ll find CNC-controlled tube benders, automated cutting stations, programmable forming equipment, and integrated welding cells for seamless assembly. Heavy-wall tubing, complex geometries, and specialty alloys are handled with the same care as simple bends. High-volume programs move quickly through automated lines, while our skilled technicians manage low-volume or highly intricate designs with precision.

This is custom tube fabrication done deliberately, engineered for reliability and performance rather than just output. By involving our engineers early in the process, we help OEMs optimize designs, control costs, and accelerate timelines.

The result: straighter tubes, cleaner cuts, and faster production with fewer downstream issues.

GSM also takes on the tube fabrication jobs that other shops turn away. Need multi-stage forming on an oversized section? We can handle it. Facing multiple part variations on a tight deadline? We can stage and sequence production without slowing your supply chain.

All of it happens under one roof—no outsourcing, no fragmented communication—just proven capability aligned with your production needs.

In tube fabrication, timing is everything, and dependable partners make the difference. GSM integrates tube bending, cutting, forming, welding, stamping, machining, and assembly into a single streamlined workflow. By combining these processes under one roof, we help OEMs stay on schedule, maintain quality, and reduce risk even when markets fluctuate.

GSM is a metal tube fabrication partner built for reliability. Instead of sending tubing to one shop for bending, another for cutting, and still another for welding or finishing, our customers leverage one coordinated system. With every stage handled in-house, we eliminate unnecessary transfers, miscommunication, and downtime.

Our tube fabrication services run on a foundation of advanced CNC benders, automated saws, precision end-forming machines, and cross-trained operators who keep production moving smoothly. Redundant equipment and flexible staffing allow us to adjust to changing schedules without jeopardizing delivery dates.

When OEMs need predictable lead times and cost control, GSM isn’t just a vendor. We’re the partner you call to stabilize your program and keep it moving forward.

Your operation deserves a partner who can produce metal tube fabrication at scale and reinforce it with a complete lineup of metal manufacturing services. GSM brings that capability to OEMs every day, across multiple sectors.

When you need tube fabrication services that keep production moving and simplify your supply chain, our experts are ready to partner with you and deliver results you can count on..

Connect with our experts, or request a quote today. Let’s build something that keeps your production stable and moving forward.

As a trusted voice in the $236.8 billion global metal stamping market, GSM answers a broad range of inquiries from OEMs evaluating our services.

Absolutely. GSM’s in-house welding, laser cutting, machining, and assembly capabilities integrate directly with tube fabrication, producing complete components ready for installation.

See what a group of middle schoolers learned during a visit to our facility in Wisconsin.

Discover why Toyota Material Handling named GSM one of its Premier Suppliers.

Learn all about Kellen Zollinger, our chief financial officer.