Middle School Students Tour GSM’s Tomah Facility

See what a group of middle schoolers learned during a visit to our facility in Wisconsin.

Home / Capabilities / Stamping

GSM provides precision metal stamping backed by a full in-house manufacturing suite: coil-fed lines, high-tonnage presses, laser cutting, welding, machining, tube processing, assembly, and more. We run prototypes and short runs up to high-volume programs.

We offer an extensive range of metal manufacturing capabilities, eliminating the need for multiple manufacturers.

We excel in providing enhanced supply chain stability and dedicated support for minimal disruptions.

We offer a state-of-the-art facility equipped to tackle projects requiring large metal components.

Our expertise helps improve manufacturability and reduce costs.

When you’re managing high-stakes production schedules and tight tolerances, you need a metal stamping partner who can keep up. General Stamping & Metalworks (GSM) delivers industrial metal stamping services built for the demands of OEMs and manufacturers who expect precision and reliability.

.

With decades of experience and one of the most capable metal stamping manufacturing operations in North America, we bring together engineering know-how, full-service production, and serious machine power, all under one roof. From high-volume stampings to oversized components for heavy equipment, we handle what others can’t.

Industrial metal stamping is the process of turning flat sheet metal into functional parts using presses and force. It’s a dependable way to produce parts at scale with speed and reliability. From simple brackets to large structural components, stamping gets it done when volume and accuracy are nonnegotiable.

Precision metal stamping is where the details matter. Holding tight tolerances. Reducing scrap. Making sure every part matches the print. That doesn’t happen without the right people, the right equipment, extensive expertise, and a production team that knows what it’s doing.

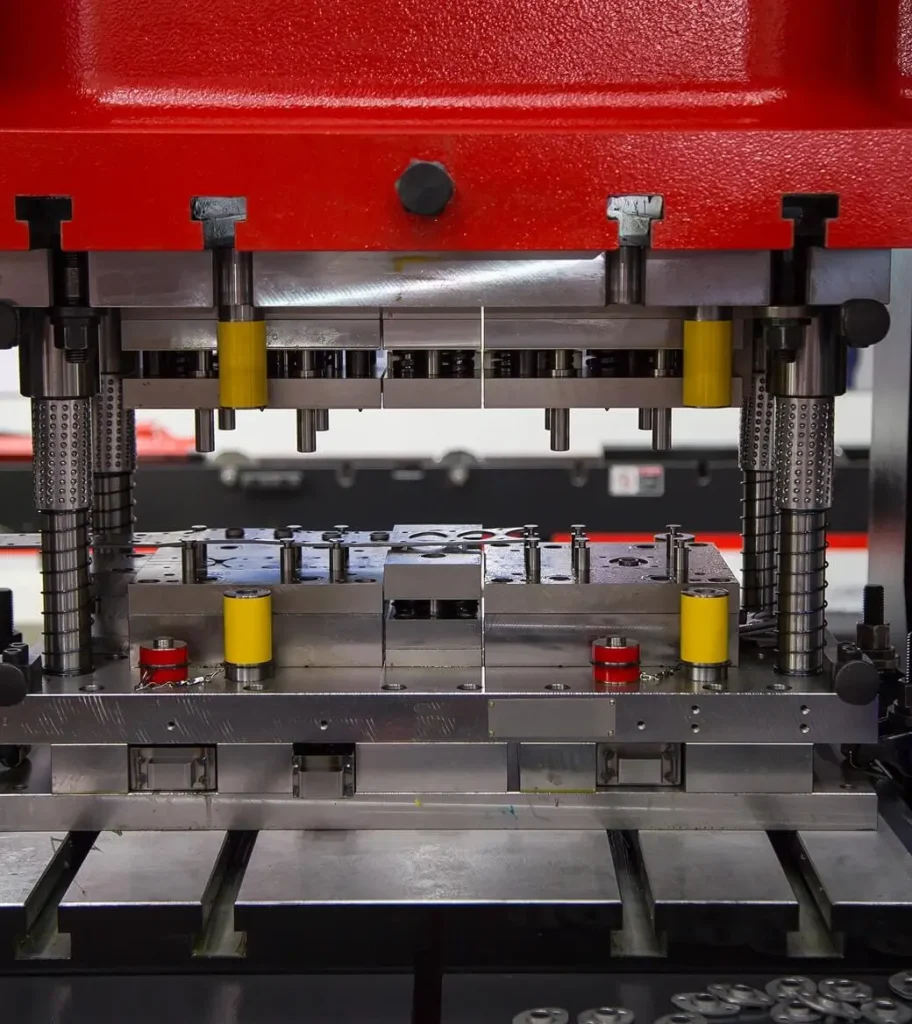

Stamping, sometimes called pressing, starts with flat sheet metal, either from coils or blanks. That material is fed into a stamping press, where it’s shaped using custom dies built for the job. Depending on the part, the press will punch, bend, coin, blank, emboss, or flange the metal into the right form. Each technique serves a purpose, and the right combination depends on material, tolerances, and the part’s end use.

At GSM, we’ve run just about every variation, supported by an unparalleled breadth of capabilities. Whether we’re producing a deep-drawn enclosure or a series of small components, we match the method to the specs and keep things efficient from press to pallet.

We build our metal stamping services for OEMs that can’t afford missed deadlines or inconsistent quality. Whether you’re running a few thousand units or managing a high-volume program, we stamp to spec, day in, day out.

Some manufacturers specialize in small runs, while others focus on high volumes. GSM handles both and everything in between. Our metal stamping manufacturing floor supports jobs of all shapes and sizes, from tight-tolerance parts that fit in your palm to oversized components that stretch over 15 feet.

We run presses up to 2,000 tons and have the in-house capacity to handle thick-gauge steel, complex geometries, and high-strength materials. Our team builds and maintains custom tooling, and our die protection systems help prevent costly errors before they happen. For programs that demand speed, we run coil-fed lines. For parts that require flexibility, we offer deep draw, progressive die, and transfer stamping setups.

This is custom metal stamping done with intention, engineered for performance, not just output. We partner with OEMs early in the process to ensure the stamped part meets all requirements without bloating the budget.

That means better part quality and faster production timelines with fewer problems downstream.

GSM also handles the jobs most stamping shops can’t touch. Need precision metal stamping for oversized truck panels? We have it covered. Running a tight deadline on multiple part variations? We can stage and sequence production without slowing down your supply chain.

It all happens here, under one roof. No outsourcing. No handoffs. Just proven capability built to match your production needs.

We all know that supply chains break down fast and that recovery isn’t always quick or cheap. When production depends on timing, and timing depends on your partners, you can’t afford to rely on vendors who overpromise and underdeliver.

That’s where GSM saves the day.

We’re a metal stamping company built for stability. Our customers don’t get bounced between suppliers or forced to piece together multiple shops just to get a finished part. We bring stamping, welding, laser cutting, tube processing, machining, and assembly together in-house, because the fewer handoffs, the fewer chances something goes wrong.

We support our metal stamping services with real production depth: multiple press lines, redundant equipment, and experienced operators who know how to keep things moving. GSM weathers the ups and downs by building a system flexible enough to absorb change and strong enough to keep pace with demand.

When OEMs want to avoid delays and cost creep, GSM isn’t just a vendor. We’re the call you make when you need your production back on track and kept there.

OEMs have options when it comes to industrial metal stamping, but few find a partner with the facilities that can handle the scope of work GSM does under one roof. That’s why so many of our customers stick with us long after the first project.

Here’s what sets us apart:

For OEMs, this combination of capability and reliability means fewer handoffs and fewer headaches with a manufacturing partner built to support long-term growth.

See how GSM tackles the toughest stamping and fabrication challenges in real time. Watch our team in action and see why leading OEMs trust us with their biggest projects.

Your production deserves a partner that can deliver industrial metal stamping at scale and back it up with the full range of metal manufacturing capabilities. That’s what GSM does every day for OEMs across industries.

If you’re looking for metal stamping services that can keep pace with your demand while also simplifying your supply chain, our team is ready to get to work.

Connect with our experts, or request a quote today. Let’s build something that keeps your production stable and moving forward.

See the results of GSM’s industrial metal stamping. We’re proud of the progressive, transfer, and deep draw work we do and are pleased to share examples with you. Every image reflects the same discipline you’ll get with your program: clean edges and parts that match the print.

As a trusted voice in the $236.8 billion global metal stamping market, GSM fields numerous questions about industrial metal stamping. Here are answers to some of the most common questions we hear from manufacturers considering GSM as their stamping partner.

Lead times vary depending on project scope, part complexity, and material availability. Most programs move from kickoff to production quickly, and our team works closely with you to align schedules with your supply chain needs.

Yes. In addition to high-volume production, GSM supports prototyping and short-run stamping so you can validate designs and refine parts before scaling.

Yes. Our in-house tool and die team designs, builds, and maintains the tooling needed to keep your stamping program efficient and reliable.

See what a group of middle schoolers learned during a visit to our facility in Wisconsin.

Discover why Toyota Material Handling named GSM one of its Premier Suppliers.

Learn all about Kellen Zollinger, our chief financial officer.